Charging towards a greener future: SUNY New Paltz engineering team prototypes more reliable EV power source

With the demand for electric cars growing as an eco-friendly alternative to gas-powered vehicles, there is an equally growing need for efficient charging options.

At SUNY New Paltz, a team of recent graduates may have uncovered a potential solution.

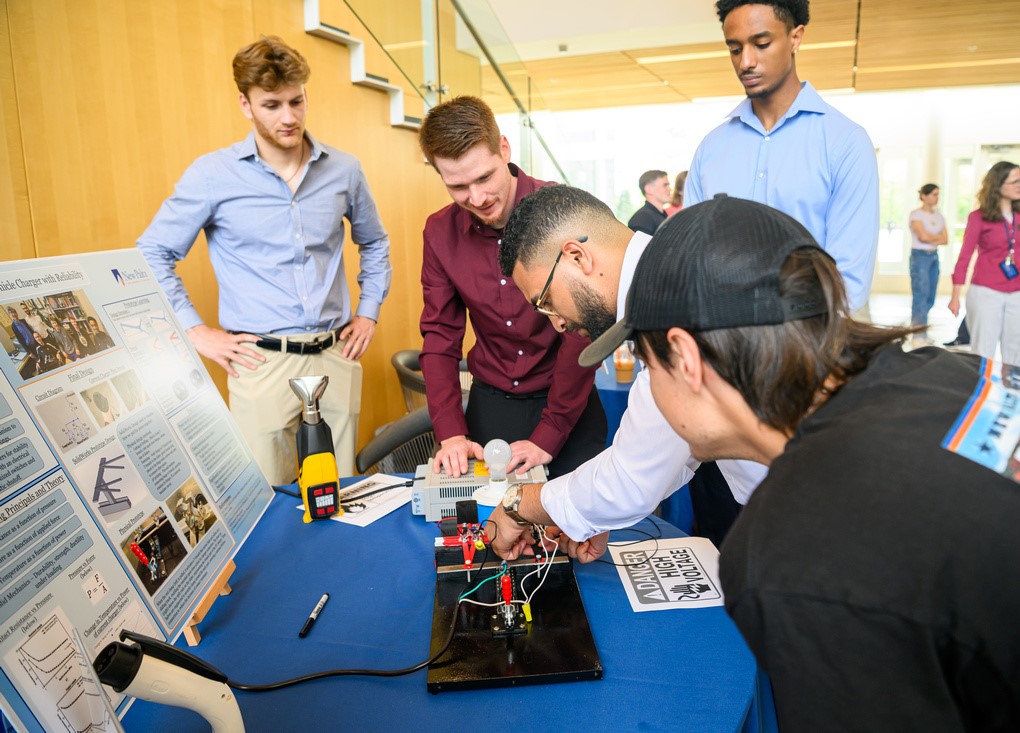

Dan Matthews ’24 (Electrical Engineering), Lucas Seyoum ’24 (Electrical Engineering), Christopher Chiera ’24 (Mechanical Engineering), Harel Yosef ’24 (Mechanical Engineering), Sean St. Lucia ’24 (Mechanical Engineering) — and their faculty mentor, Assistant Professor Ping-Chuan Wang — teamed up with local engineering firm IKM Technology in Hopewell Junction, New York, to develop a prototype for an Efficient Electric Vehicle Charger.

“This project appealed to me from the start,” said Matthews. “It felt exciting to know we could create something that could help people.”

The project started when Kai Di Feng, founder and lead consultant of IKM Technology, contacted Wang, a former colleague of his at IBM, as the firm was exploring issues with electric vehicle charging.

In recent years, as electric vehicle charger production has ramped up to meet a growing demand, the rapid pace of production has caused some incidental mechanical inefficiencies. Among these is an issue with friction where the chargers make electrical contact, which can lead to resistance and overheating, and ultimately may result in energy waste, charger deterioration, and fire hazards.

“It is clear that electric vehicles will replace traditional gasoline cars in the near future, and battery charging is key to their deployment,” said Feng. “Existing charging guns have a reliability issue, and I knew I could trust Dr. Wang and his students to help our team.”

“This was a daunting task, but our students stepped up to the challenge with their passion and innovative approach,” said Wang.

Both the mechanical and electrical engineering students played to their strengths and skill sets in formulating their EV charger prototype. Chiera, Yosef and St. Lucia determined how it could be built on a small scale, given the relatively short timeline of several months, while Matthews and Seyoum tinkered with ways current could flow successfully within their prototype without causing overheating.

Eventually, they found that a clamping mechanism bridging the socket with the prongs of the charger can create connectivity without friction. The design was conceptualized in consultation with Mahdi Farahikia, Assistant Professor of Mechanical Engineering, and the prototype was later assembled for feasibility demonstration.

“The prongs still make contact with the socket, but the clamp is there to prevent wear and tear.” said Yosef. “The idea is that you can plug your car in, and it starts charging once the clamping is engaged.”

Were this mechanism to be implemented in future EV chargers, it could change the electric vehicle manufacturing game by creating a pathway for more robust charging stations.

“It’s still a young industry, so we were proud to contribute to its evolution in this way,” said Yosef. “We hope this project only grows following our graduation.”

Click here to learn more about SUNY New Paltz’s Division of Engineering Programs.