A massive new fiber analysis project is underway in the Division of Engineering Programs at SUNY New Paltz, with the potential transform the way farmers and manufacturers do business in New York State.

Assistant Professor Jared W. Nelson received a significant grant late last year from the non-profit organization FuzeHub to purchase state-of-the-art equipment for testing the physical properties of natural fibers, positioning the College as a leading research hub in an emerging sector of New York State industry.

Many manufacturers view natural fibers, such as flax, hemp, bamboo and kenaf, as durable, affordable and sustainable alternatives to synthetic materials, and farmers are eager to partner with entrepreneurs to produce what they need.

“We want to help both ends of the supply chain – helping manufacturers identify key product areas where these fibers can be used, and helping farmers understand how to grow and process fibers for specific applications,” Nelson said. “Our goal is to understand variability. We’re looking to compare groups that were grown under different conditions, but in order to do that we need to test thousands of samples.”

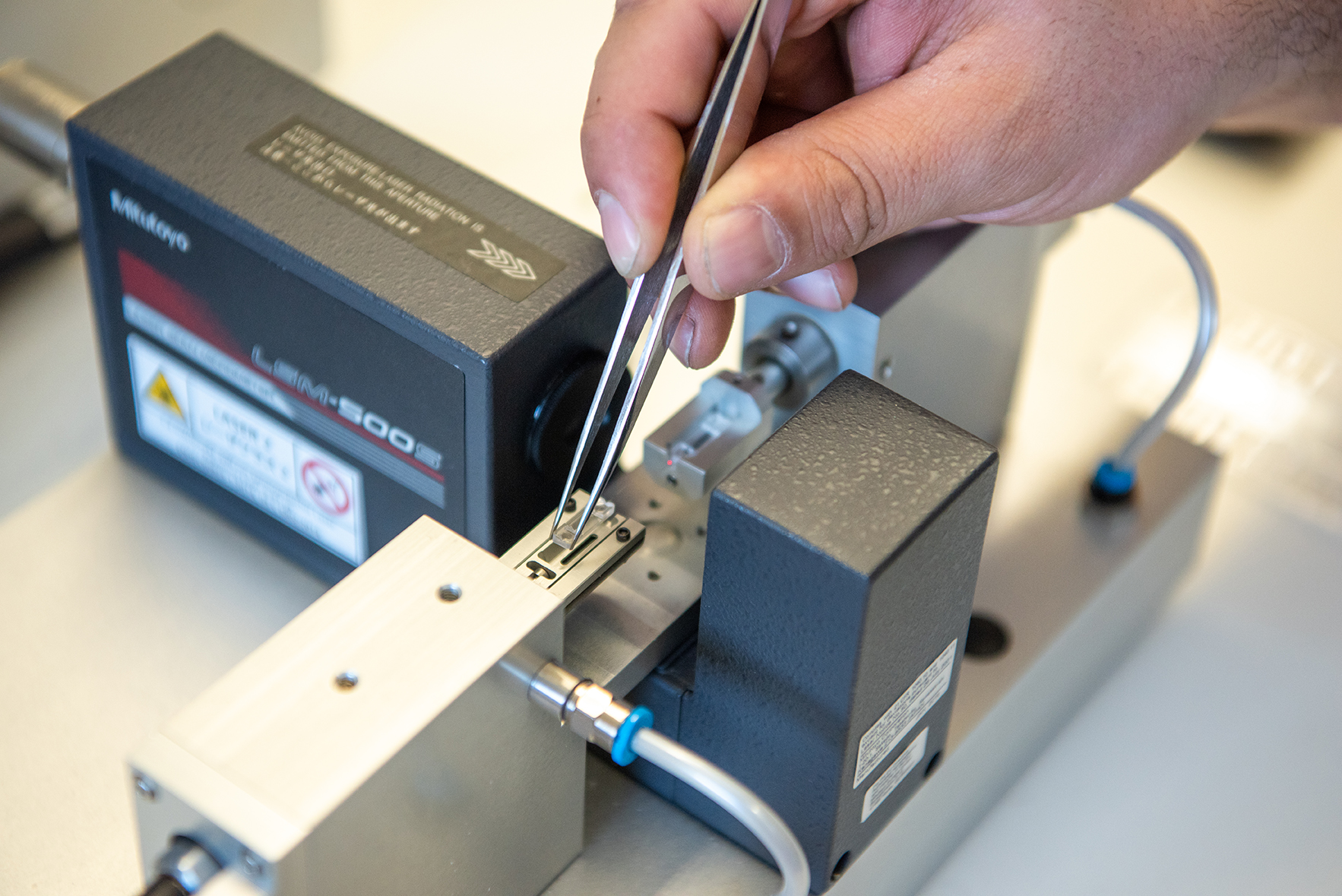

“Grooves in the machine help align the fiber automatically,” Bereday said. “It enables more repeatable and more accurate results.”

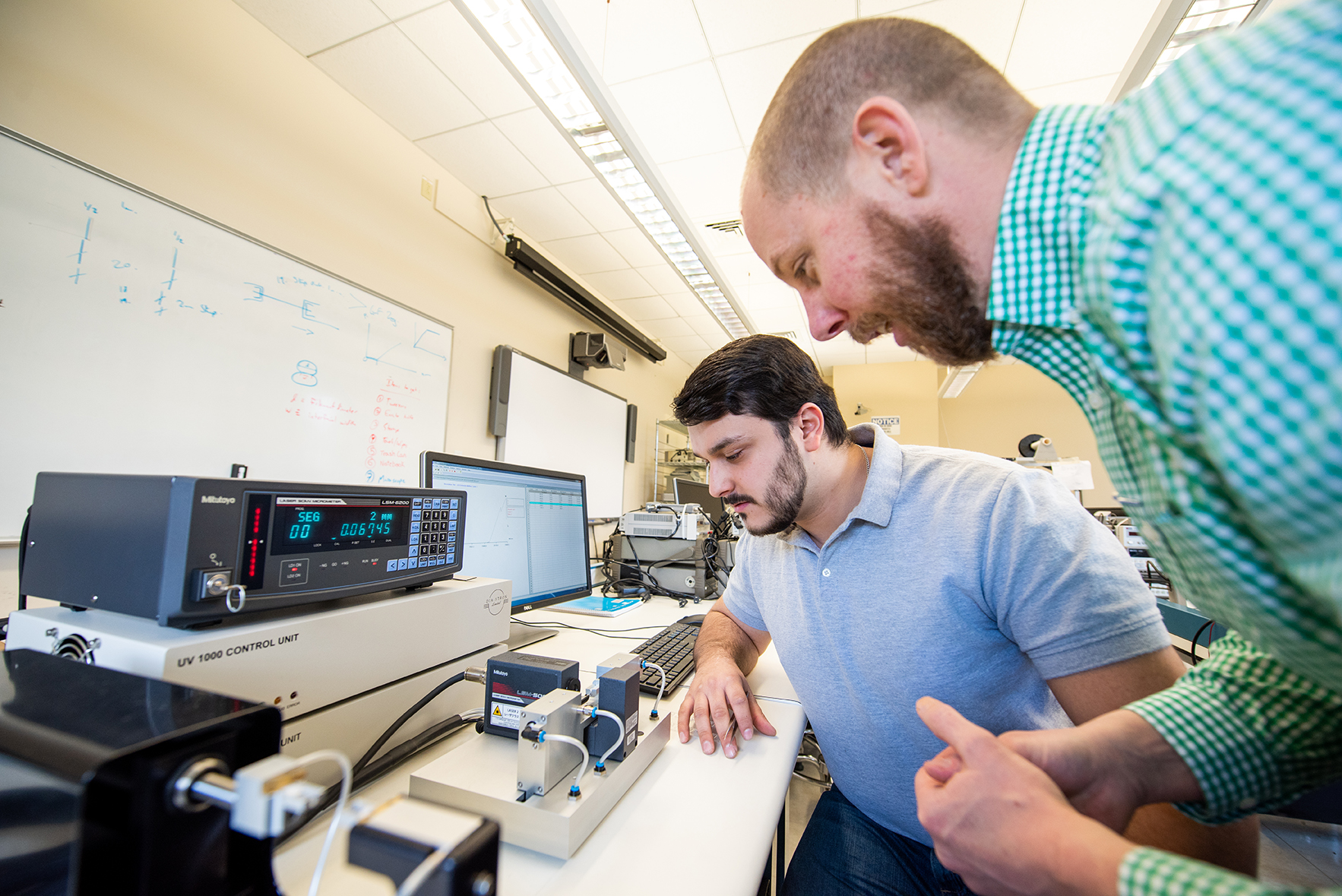

The scale of the project has created opportunities for undergraduate students to gain valuable research experience working alongside Nelson in his lab.

Sigmund “Siggy” Bereday ’18 (Mechanical Engineering), of Irvington, N.Y., jumped at the chance to get those reps during the spring semester, his last at New Paltz before graduation.

“I always knew I wanted to be an engineer,” Bereday said. “I was the kind of kid who was really hands-on, taking apart my bike, putting it back together, and hoping it would work again.”

As one of the first students to enroll in mechanical engineering when the major became available in 2014, Bereday has witnessed the program’s growth firsthand.

“When I started, I think there were 13 of us,” he said. “Now there’s about 100, with new equipment and other resources. It’s a great balance, like what I always pictured engineering being about: small classes, close relationships with teachers, and partners and friends you can rely on for help.”

Bereday found his niche in Nelson’s materials science courses. In fall 2017, he conducted an independent study of a range of fiber testing methods, and he went on to assume a central role in the materials analysis that began this spring.

“This kind of research is a lot of work, but Siggy really threw himself into it,” Nelson said. “He understands the full benefits of our new equipment, and he became a leader of our fiber testing effort.”

Bereday added to his resume throughout the semester. He participated in trainings with the company that produces the equipment, and has become proficient using the software, UVWin, which is key to organizing the massive quantities of data the machine observes.

For an undergraduate student approaching graduation, it was an ideal experience: hands-on work with clear connections to both research and industrial applications, with the potential to have an immediate real-world impact.

“There’s so many roads I could go down as a mechanical engineer,” Bereday said. “Working with natural fibers is a growing opportunity – there are clear sustainability benefits of using natural fibers instead of synthetics, so there’s more testing being done, and more end-uses being developed all over the country.”

Visit the Division of Engineering Programs to learn more about offerings in mechanical, computer and electrical engineering at SUNY New Paltz.